Just a note about removing the mainshaft bearings, they make a bearing remover that slides behind the bearing snap ring that makes removing the bearing a breeze but itís not needed. After removing the snap ring I used a brass drift working from inside the case to remove the rear bearing. I left the lock ring on the front bearing and used a dead blow hammer on the tip of the clutch shaft to remove the bearing. Both front and rear mainshaft bearings are ball bearing type opposed to the cylindrical or tapered roller bearing.

I next removed the lock plate from the rear of the case that locks the countershaft and reverse idler gear shaft. I tapped out the countershaft to the rear of the case using a brass drift once the shaft was out I was able to remove the countershaft gear assembly. The countershaft assembly has 88 roller bearings and the reverse idler has 74 bearing rollers.

The reverse idle gear shaft does not come out as easily as the countershaft because the front of the shaft is located inside the case unlike the countershaft that is on the outside of the case. I used a long extension and dead blow hammer.

Note the magnet at the bottom of the case itís a well thought out option.

I cleaned the case for a second time and chased all threads as well. I used a 5/16 bit and drilled 2 holes for the adapter.

After cleaning the burs I tapped the hole using a 3/8Ē 16 tap. You can drill a hole in a block of wood and use it to keep the tap going in straight I chose to use a torpedo level it worked for me.

I test fit the adapter and all holes lined up perfectly.

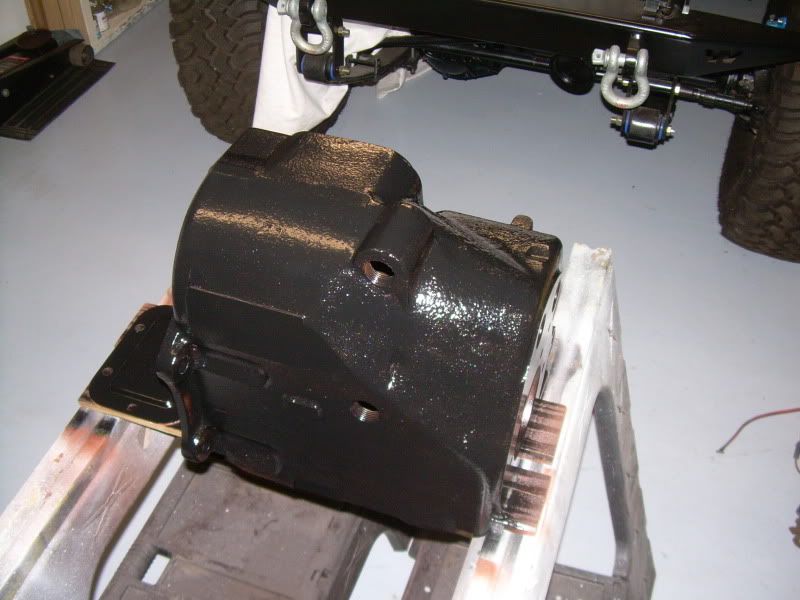

I cleaned the case of metal filings, washed, and prepped for paint.